Products

CNC Vertical Machining Center

- Advanced Multi-Tasking Lathe

- CNC turning and milling complex lathe

- CNC Turret lathe

- Sliding Headstock Automation CNC lathe

- Other

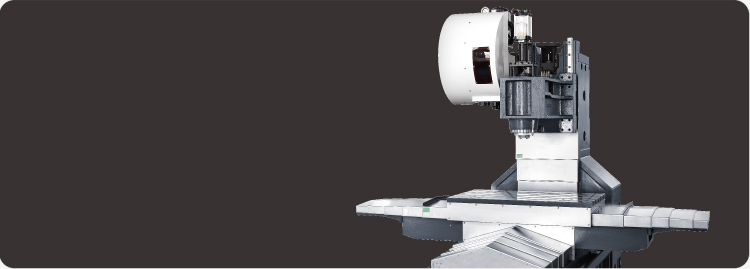

Q10

VERTICAL MACHINING CENTERS

- Hardware, molds, automotive parts, communication, medical devices and aerospace

- The optional bed construction design is able to resist inertia generated by high "G" with maximum stability.

- The short nose spindle presents outstanding rigidity. It also increases efficiency while lowering tool wear.

- 36 meters rapid traverse on three axes greatly reduces machining time.

- Stable automatic tool change system not only reduces non-cutting time, but also extends spindle life.

- Front side chip exhaust with optimal chip exhausting angles and extra large chip flushing rate.

Highlight:

Specification

| Mitsubishi Controller M70 | |||||

| Travel | X-axis travel | 1000mm | Table | Table size (mm) | 1200x550 |

|---|---|---|---|---|---|

| Y-axis travel | 600 mm | T-slot (W×No.×Pitch) | 18x5x95 mm | ||

| Z-axis travel | 600 mm | Table loading capacity | 600 kg | ||

| Spindle | Spindle nose to table | 120~720 mm | ATC | Tool selection method | Arm type |

| Type of spindle | BT-40 | No. of tools | 24 pcs | ||

| Spindle transmission | Belt Drive | Max. tool weight | 7 kgs | ||

| Spindle R.P.M. | 8,000 rpm |

Coolant system and power |

Coolant tank capacity | 250 L | |

| Spindle motor | 11 kw | Air pressure | 6 kg | ||

| Feedrafe | X/Y/Z rapid traverse | 36 / 36 / 36 M/min | Power requirement | 20 KVA | |

| Three axes ball screws (mm) | ø40 / P12 / C3 | ||||

| Three axes linear guide(P class) |

X-axis linear guide: roller type 35 mm x 4 blocks Y, Z-axis linear guide: roller type 45 mm x 4 blocks |

Machine size | machine size (LxWxH) (mm) | 2950X2500X2950 | |

| Three axes transmission method | Direct drive | Max. machine weight | 5600 kg | ||

| Cutting feed rate | 1~10,000 mm/min | ||||

Products Download