CNC turning and milling complex lathe

- Advanced Multi-Tasking Lathe

- CNC turning and milling complex lathe

- CNC Turret lathe

- Sliding Headstock Automation CNC lathe

- Other

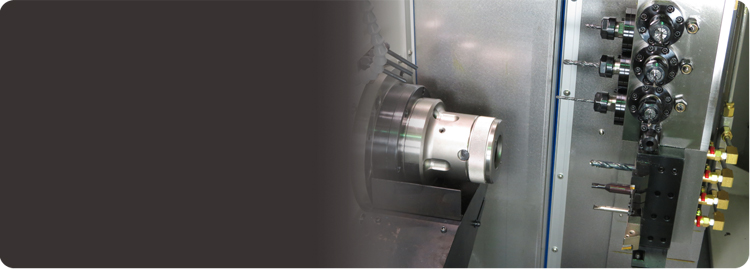

i-42 ECO

This gang tooling lathe is an affordable alternative to a turret type,C-axis lathe.

The tooling system comprises of 6 turning, 4 boring and 6 live milling tools giving a capacity of 16 tools.

lts unique design allows for rapid chip to chip times, which will generally out perform turret type machines, enabling a reduction in cycle times.

lts rigid design allows heavy duty cutting to be performed, and the 6 live tooling spindles with both C-axis and Y-axis, can complete the most complex of work pieces in one operation.

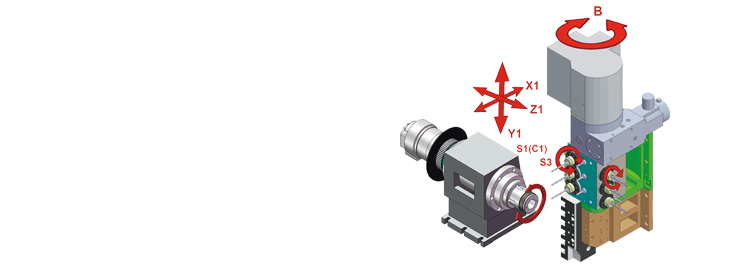

i-42 Eco B TOOLING SYSTEM

The milling head with 12 motorized tools and 360 degrees continuous rotating is significantly efficient productivity for small and medium lot size pieces.

Axial view

i-42 Eco B

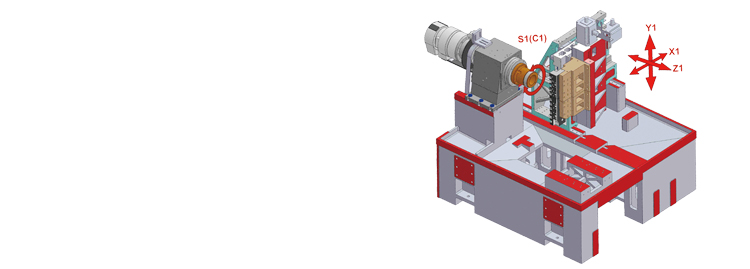

i-42 Eco TOOLING SYSTEM

The standard i42-Eco is comes with 42mm spindle,11 OD and 9 ID tool turning to achieve the job shop mass production.

Axial view

i-42 Eco

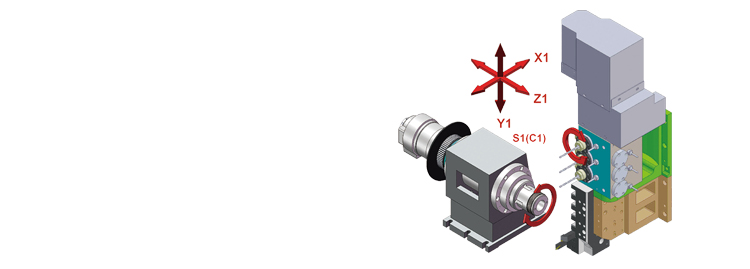

i-42 Eco M TOOLING SYSTEM

Standard machine packed with 6 live tools and C-Axis control, many complex contours can be machined, providing a variety of options to our customers.

Axial view

i-42 Eco M

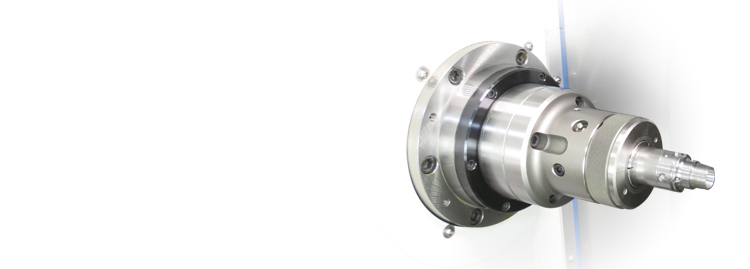

SPINDLE

The cartridge type spindle runs on P4 high precision bearings giving high radial and axial stability, allowing for heavy duty cutting.

The spindle is assembled and tested in a temperature controlled clean room, sealed, and requires no maintenance. The spindle housing is large, and symmetrically ribbed to allow heat dissipation and thermal stability.

LINEAR GUIDEWAYS

The machine is equipped with high precision, HIWIN linear guideways.

The use of 35mm rails throughout the machine increases stability and accuracy, and allows heavier cuts to be achieved.

Specification

| Machine Type | I-42ECO | |||||

| Mitsubishi Controller | M80 | |||||

|

Spindle

Capacity

|

Max. Turning Dia. | 100mm | ||||

| Max. Bar Working Dia. | 42mm (65mm) | |||||

| Max. Turning Length | 230mm | |||||

| Collet Chuck Type | KK5-173E42B (KK6-185E60B) | |||||

| Spindle Nose | A2-5 (A2-6) | |||||

| Spindle Bore | 43mm (66mm) | |||||

| Max. RPM. | 4000rpm (6000rpm) | |||||

|

Sub-spindle

Capacity

|

Max. Turning Dia. | ---- | ||||

| Max. Bar Working Dia. | ---- | |||||

| Max. Turning Length | ---- | |||||

| Collet Chuck Type | ---- | |||||

| Spindle Nose | ---- | |||||

| Spindle Bore | ---- | |||||

| Max. RPM. | ---- | |||||

| Travel&Feed | X1/Y1/Z1 axis | 150 / 410 / 250mm | ||||

| X2/Y2/Z2 axis | ---- | |||||

| Rapid Feed | 30m/min | |||||

| Motor | Main-Spindle | Servo Spindle 7.5kw (11.0kw) | ||||

| Sub-Spindle | ---- | |||||

| X1/Y1/Z1 axis | AC Servo 1.0 / 1.5 / 1.5kw | |||||

| X2/Y2/Z2 axis | ---- | |||||

| Motorized Tool | AC Servo 1.5kw | |||||

|

A.T.C System

|

OD/ID Tools Main Spindle | I-42 Plus | I-42 Plus M | I-42 Plus B | ||

| 11 / 9 | 6 / 5 | 6 / 5 | ||||

| OD/ID Tools Main Spindle | ---- | |||||

| Tool Shank Size | □ 20mm | |||||

| Drill Holder Size (Main) | ER-20 / Ø20mm | |||||

| Drill Holder Size (Sub) | ---- | |||||

|

Motorized Tool

|

Number of Motorized Tools | I-42 Plus | I-42 Plus M | I-42 Plus B | ||

| 0 | 6 | 12 | ||||

| Max. RPM. | 4000rpm | |||||

| Collet Specification | ER-20 | |||||

| Max. Drilling Dia. | 12.0mm | |||||

| Max. Tapping Capacity | M10xP1.5 | |||||

|

Hydraulic

System

|

Hydraulic Pump / Tank Capacity | 1HP / 40L | ||||

|

Max. Pressure / Flow

|

30 kg/cm² / 12L/min | |||||

| Lubrication | Lubricant Pump / Tank Capacity | 25W / 2L | ||||

| Max. Pressure |

15 kg/cm²

|

|||||

|

Coolant

System

|

Coolant Pump | TPH4T5K, 5Bar, 75 L/min | ||||

| Hydraulic Pump | ---- | |||||

|

Coolant Tank Capacity

|

125L | |||||

|

Machine

Size

|

Length/ Width/ Height | 3200 (2500) / 1750 / 1950mm | ||||

| Weight |

3780kg

|

|||||

| ( ) Option | ||||||

Products Download