Advanced Multi-Tasking Lathe

- Advanced Multi-Tasking Lathe

- CNC turning and milling complex lathe

- CNC Turret lathe

- Sliding Headstock Automation CNC lathe

- Other

S42 ATM

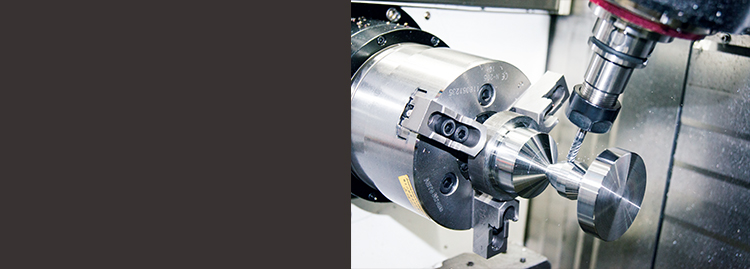

The medical market is highly regulated, require high precision, performance and reliability; lives depend on accurate machining performed by experienced professionals.

The new S42 delivers successful medical machining solutions for a wide range of products, This field continues to grow in complexity parts and new S42 help to achieve any challenge. Whether taking on titanium, chrome, stainless steel or extreme precision of micromachining, the S42 fulfills the engineering solutions for one-process manufacturing.

Specification

| Machine Type | S-42 ATM | |||

|

Mitsubishi Controller

|

M830S | |||

|

Spindle

Capacity

|

Max. Bar Working Dia. | 42mm | ||

|

Max. Turning Length

|

350mm(OD Turn) / 140mm(Drill) | |||

| Collet Chuck Type | KK5-173E42B / N205A5 (5-inch) | |||

| Spindle Nose | ISO(DIN) A2-5 | |||

| Spindle Bore | 43mm | |||

| Max. RPM. | 6000 rpm | |||

| Spindle Motor | spindle 11kw | |||

|

Sub-spindle

Capacity

|

Max. Bar Working Dia. | 42mm | ||

| Max. Turning Length | 230mm(OD Turn) / 55mm(Drill) | |||

| Collet Chuck Type | KK5-173E42B / N205A5 (5-inch) | |||

| Spindle Nose | ISO(DIN) A2-5 | |||

| Spindle Bore | 33mm | |||

| Max. RPM. | 6000rpm | |||

| Spindle Motor | Built-in spindle 3.7kw | |||

| Optional Accessory 1 | Ø16Running center (Quill) | |||

| Optional Accessory 2 | Part Support (pneumatic) | |||

| Tool Spindle | Max. RPM. | 12000rpm | ||

| Spindle Type | HSK-T40 | |||

| Spindle Motor | Built-in spindle 10kw | |||

| Tool Holding Force | 290kg | |||

| Tool Realease Force | 450~500kg | |||

| Machining Cooling | Coolant Ring | |||

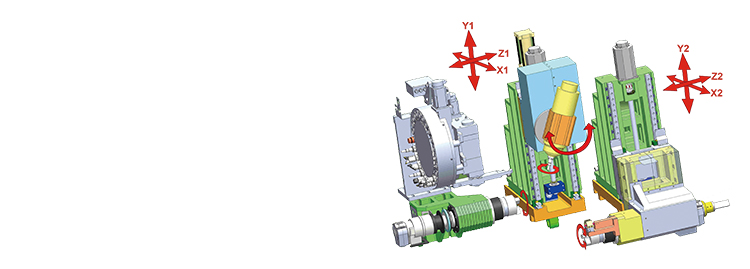

| Travel&Feed | X1 | 420mm (210mm) | ||

| Y1 | 80 = ±40mm | |||

| Z1 | 400mm | |||

| X2 | 420mm (210mm) | |||

| Y2 | 80 = ±40mm | |||

| Z2 | 510mm | |||

| X1/Y1/Z1 Axis Servo Motor | 2.2 / 1.5 / 2.2 kw | |||

| X2/Y2/Z2 Axis Servo Motor | 2.2 / 1.5 / 2.2 kw | |||

| B Axis | B axis Rotary | 190°= ±95° | ||

| Motor | AC Servo 1.0kw | |||

| ATC System | Tool Spec | HSK-T40 | ||

| Tool Magazine Station | 24 | |||

| Tool Retract Travel | 40mm | |||

| Max. Tool Dia. | Ø55 (φ80 witdout adjacent tool) | |||

| Max. Tool Weight | 3kg | |||

| Max. Tool Length | 100 (From tde surface of spindle) | |||

| Tool Change Time | 1.3sec | |||

| Tool Arm Swing | 505mm | |||

| Motor | AC Servo 0.75kw | |||

| Gantry Tooling | Drill Holder Spec | ER20 / Ø20mm | ||

| Tool Quantity | 6 | |||

| Lubrication | Max. Pressure | 10MPa (100 kg/cm²) | ||

| Flow | 20cc/min | |||

| Capacity | 1L | |||

| Oil Spec | lubrication oil (#0~00) | |||

|

Hydraulic

System

|

Hydraulic Motor | 1HP | ||

| Hydraulic Pressure | 50kg/cm² | |||

| Tank Capacity | 35L / 30L | |||

|

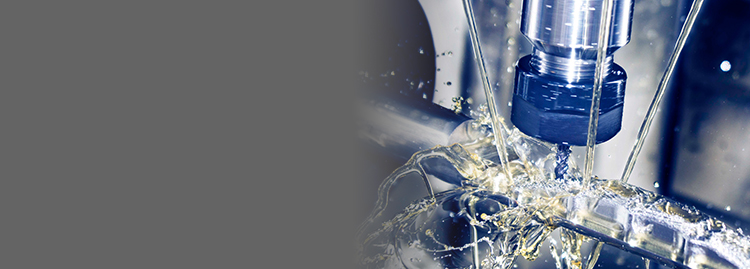

Coolant

System

|

Coolant Tank Capacity | 240L | ||

| Coolant Motor Type | 2KW + 2KW | |||

| Pressure | 5BAR + 25BAR | |||

|

Machine

Size

|

Length | 3800mm (Chip CVY.) / 2900mm | ||

| Width | 2200mm | |||

| Height | 2050mm | |||

| Weight | 4350kg | |||

| ( ) Option | ||||

Products Download