Advanced Multi-Tasking Lathe

- Advanced Multi-Tasking Lathe

- CNC turning and milling complex lathe

- CNC Turret lathe

- Sliding Headstock Automation CNC lathe

- Other

T8 Hybrid-Y

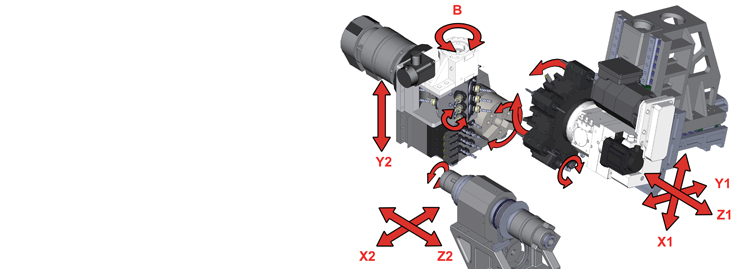

Cycle time can be saved up to 45%. Flexible duo system simultaneous. The system allows running 2 programs simultaneously

- Power turret and flexible gantry type tooling system.

- Synchronous spindles.

- Up to 24 live tools with powerful motor.

- Double programs for cycle time saving.

- 25 bar coolant pressure.

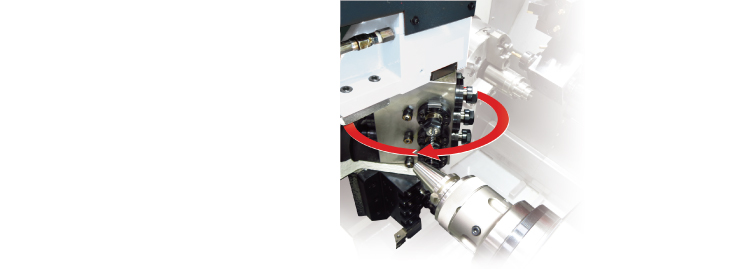

- Free angle B axis 360° for all the angular tapping and drilling.

- 2 Y axis.

Feature:

AXIS

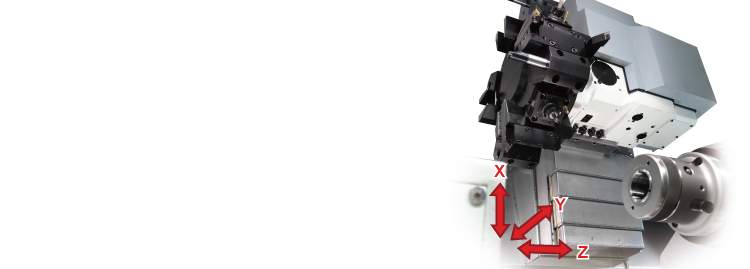

The turret is mounted on a secondary 75 degrees wedge saddle on top of the X-axis slide from one - piece casting. Both X & Y axes have extra wide hardened and linear ways to assure the rigidity and accuracy. Y-axis control further enhances multi-tasking live tooling capabilities and improves various machining precision. With Y-axis travel 80 mm=±40mm , a wide variety of parts can be efficiently machined.

The modern slant-bed design

ensure easy chip disposal and heat elimination.

BMT-55

Turret with 12 stations can be additionally equipped with driven tools on six stations. In connection with the driven tools, the main spindle is C-axis functional for accurate positioning.

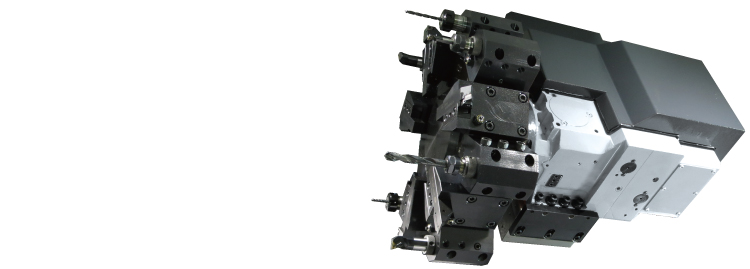

Gantry Tooling B-Axis Free angle Tilting drilling and tapping

The unique gantry tooling system is extremely flexible. The standard tooling system allows for 5 external tools, 9 internal tools and 12 live tools. The ER20 spindles are gear driven, with rigid tapping as standard. Up to 26 tools load for machining

Display

The large high resoultion display packed with intelligent coversation programming and path simulation

Specification

| Machine Type | T8 Hybrid-Y | |

|

Mitsubishi Controller

|

M830S | |

|

Main

Spindle

Capacity

|

Swing over Bed | 500mm |

| Swing over cross slide | 300mm | |

| Max. Turning Dia. | 300mm | |

| Max. Bar Working Dia. | 65mm | |

| Max. Turning Length | 200mm | |

| Chuck Size | KK6-185E60B | |

| Main Spindle Nose | A2-6 | |

| Main Spindle Bore | 66mm | |

| Max. RPM. | 3000rpm (4000rpm) | |

|

Sub- Spindle

Capacity

|

Max. Turning Dia. | 100mm |

| Max. Bar Working Dia. | 42mm | |

| Max. Turning Length | 100mm | |

| Chuck Size | KK5-173E42B | |

| Sub- Spindle Nose | A2-5 | |

| Sub- Spindle Bore | 32mm | |

|

Max. RPM.

|

4000rpm (6000rpm)

|

|

|

Tavel&Feed

|

Slant Bed Degree | 75° |

| X1/Z1 Axis Travel | 150mm / 380mm | |

| Y1 Axis Travel | 80mm = ±40mm | |

|

X2/Y2/Z2 Axis Travel

|

470mm / 380mm / 280mm

|

|

| Axes | Ball screw | Ø32 x P10 |

| Linear Guide Way | 35mm | |

| Y2 Axis Linear Guide Way | 25mm | |

| Rapid Feed | 30m/min | |

|

ATC

System

|

System 1 | BMT-55 Power Turret |

| No of Tools | 12 | |

| Tool Holder | □25mm / ○ 25mm / ○ 32mm | |

| System 2 | Gantry | |

| No of Tools | OD*5 / ID*9 / LiveTool*12 | |

|

Tool Holder

|

□20mm ○ 20mm

|

|

|

Motor

|

Main Spindle | Servo Spindle 11kw |

| Sub Spindle | Servo Spindle 3.7kw (5.5kw) | |

| X1/Y1/Z1 Axis | AC Servo 2.2 / 1.5 / 1.5kw | |

| X2/Y2/Z2 Axis | AC Servo 1.5 / 1.5 / 1.5kw | |

|

Hydraulic

System

|

Pump Spec/Capacity | 1HP / 40L |

| Hydraulic Pressure/ Flow | 30 kg/cm² / 12L/min | |

| Lubrication | Pump Spce/Capacity | 25W / 2L |

| Max. Pressure | 15 kg/cm² | |

|

Coolant

System

|

Pump Spec | TPH4T5K, 5Bar, 75 L/min |

| High Pressure Pump Spec | SF-30C, 25Bar, 30L/min | |

| Coolant Tank Capacity | 240L | |

|

Machine

Size

|

Length without/with Chip Coveyor | 2795mm/4118mm |

| Machine Width/Height | 2051mm/2180mm | |

| Machine Weight | 6100 kg | |

| ( ) Option | ||

Products Download